Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Toshiba RAS-10SA-E

-

Page 2: Table Of Contents

1. SPECIFICATIONS ... 4 2. CONSTRUCTION VIEWS ... 6 2-1. Indoor Unit ... 6 2-2. Outdoor Unit ... 7 3. WIRING DIAGRAM ... 8 4. SPECIFICATIONS OF ELECTRICAL PARTS ... 9 4-1. Indoor Unit ... 9 4-2. Outdoor Unit ... 9 5. - Page 3 9. TROUBLESHOOTING CHART ... 32 9-1. What to be Prechecked First ... 32 9-1-1. Power Supply Voltage ... 32 9-1-2. Incorrect Cable Connection between Indoor and Outdoor Units ... 32 9-1-3. Misleading but Good Operations ...33 9-2. Primary Judgement of Trouble Sources ... 34 9-2-1.

-

Page 4: Specifications

Single 220/230/240 0.83/0.85/0.88 95/92/90 230V 240V 0.15/3.87 0.15/3.92 44/36/31 44/45/45 R-22 0.73 Capillary tube 9.52 Flare connection 6.35 Flare connection RAS-10SK-E/RAS-10SKX Finned tube Cross flow fan RAS-10SA-E/RAS-10SAX Finned tube Propeller 1600 PH102T1-4C Fuse, Overload relay 21 ~ 43 240V 2.70... - Page 5 Note : *1 • Capacity is based on the following temperature conditions. Temperature Indoor unit inlet air temperature Outdoor unit inlet air temperature Notes : *2 CHARGELESS • No additional refrigerant required. • This air conditioner accepts a connection piping length of up to 10m and a head of up to 5m. •...

-

Page 6: Construction Views

2-1. Indoor Unit RAS-10SK-E RAS-10SKX Air inlet Air outlet Drain hose (0.54m) Hanger Connecting pipe (0.39m) (Flare ø9.52) 65.5 Hanger Minimum distance to wall 120 or more Hanger Center line 2. CONSTRUCTION VIEWS Heat exchanger Air filter @@@@@@ PPPPPP @@@@@@ PPPPPP @@@@@@ PPPPPP... -

Page 7: Outdoor Unit

2-2. Outdoor Unit RAS-10SA-E RAS-10SAX Detail Drawing ø6 Hole ø11x14 Hole Handle ø25 Drain hole 8-ø6 Holes (For fixing the outdoor unit) 4-ø11x14 Long holes (For anchor bolt ø8-ø10) Fan guard ø420 View Inlet port Inlet port 100 or more... -

Page 8: Wiring Diagram

Model Section A RAS-10SK-E/SA-E 220/230/240V ~ 50Hz RAS-10SKX/SAX 220/230/240V ~ 50Hz SG01 GRN&YEL Section A POWER TERMINAL RY02 BLOCK INDOOR TERMINAL BLOCK OUTDOOR TERMINAL BLOCK OVER LOAD RELAY FAN MOTOR COMPRESSOR 3. WIRING DIAGRAM LOUVER MOTOR THERMAL FUSE 77˚C x 2 CN04 R109 R116... -

Page 9: Specifications Of Electrical Parts

Line filter (L01) Diode (DB01) Capacitor (C02) Fuse (F01) Power supply IC (IC01) Varistor (R21, R109) Resistor (R01) Louver motor 4-2. Outdoor Unit RAS-10SA-E RAS-10SAX Parts name Compressor Fan motor (for outdoor) Running capacitor (for fan motor) Running capacitor (for compressor) -

Page 10: Refrigerant Cycle Diagram

5. REFRIGERANT CYCLE DIAGRAM RAS-10SK-E / RAS-10SA-E RAS-10SKX / RAS-10SAX Cooling 0.39m (Connecting pipe) ø9.52 O.D.:9.52mm Packed valve (ø9.52) Accumulator Compressor PH102T1-4C 50Hz Standard Cooling High temperature Low temperature Note : • Measure the heat exchanger temperature at the center of U-bend. (By means of TC sensor.) -

Page 11: Micro-Computer Block Diagram

6. MICRO-COMPUTER BLOCK DIAGRAM – 11 –... -

Page 12: Operation Descriptions

7-1. FAN ONLY Operation (MODE of the remote control : FAN ONLY) (1) During this mode, the relay RY01 is always turned off so that only the indoor fan is operated. RY02 is always turnd on. FAN-ONLY display is lit. 1) When the FAN is set to AUTO, the indoor fan motor operates as shown in Fig 7-1-1. -

Page 13: Louver Control

7-2-1. Louver Control (1) By pushing the SET button of the remote control during the operation, the louver can be set to the desired position. And the louver position is stored in the microcom- puter, the louvers will be set to the position au- tomatically at the next operation. -

Page 14: Auto Operation

7-4. AUTO Operation (MODE of the remote control : AUTO) (1) One of the 2 modes, Cooling or Dry is selected according to room temperature at which operation is to start, as shown in Fig. 7-4-1. The Fan mode will continue until room temperature reaches a level at which another mode is selected. -

Page 15: Econo. Mode

7-5. ECONO. Mode When the ECONO. button is pushed, during COOL and AUTO operation, the OPERATION display is turned off and the ECONO. display is lit and the indoor unit operates quietly and mildly with controlling airflow. 7-5-1. Cooling (1) In the ECONO. mode, the set temp. by the remote control is changed automatically as shown in Fig. -

Page 16: Auto Restart Function

7-7. Auto Restart Function This unit is equipped with an Automatic restarting facility which allows the unit to restart and resume the set operating conditions in the event of a power supply shutdown without the use of the hand control. The operation will resume without warning three minutes after the power is restored. -

Page 17: How To Cancel The Auto Restart

7-7-2. How to Cancel the Auto Restart To cancel the Auto Restart function, proceed as follows: Repeat the setting procedure: the unit will acknowledge the instruction and bleep three times. • When the system is stand-by (not running) OPERATION Press the TEMPORARY button continuously more than three seconds. -

Page 18: Installation Procedure

And make sure the equipment to be earthed. • Appliance shall be installed in accordance with national wiring requlations. If you detect any damage, do not install the unit. Contact your Toshiba dealer immediately. 8. INSTALLATION PROCEDURE For general public use... - Page 19 CAUTION • Exposure of unit or water or other moisture before installation will result in an electrical short. Do not store in a wet basement or expose to rain or water. • After unpacking the unit, examine it carefully for possible damage. •...

-

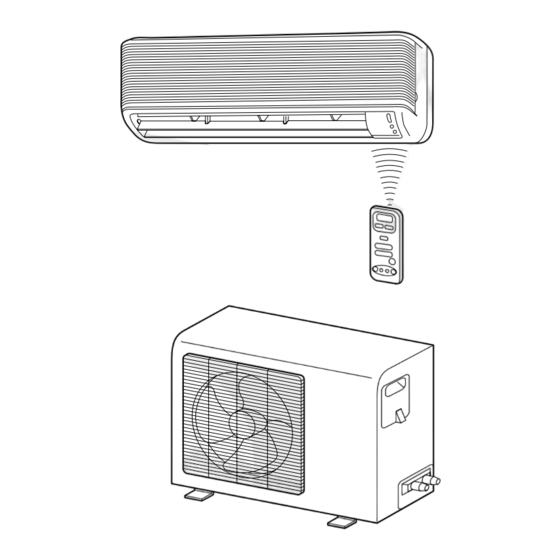

Page 20: Installation Diagram Of Indoor And Outdoor Units

8-2. Installation Diagram of Indoor and Outdoor Units For installation of the indoor unit, use the paper pattern on the back. 3 Clip anchor Front cabinet Front panel Filter frame 9 Deodorizing filter 10 Purifying filter Before install the wireless remote control •... -

Page 21: Installation

8-3. Installation 8-3-1. Optional Parts Part Parts name code Refrigerant piping Liquid side : ø6.35 mm Gas side : ø9.52 mm Pipe insulating material (polyethylene foam, 6 mm thick) Putty, PVC tapes <Anchor bolt arrangement of outdoor unit> 8-3-2. Installation Parts Part Name of parts Q’ty... -

Page 22: Indoor Unit

8-4. Indoor Unit t Installation place • A place which provides the spaces around the indoor unit as shown in the diagram in section 8-2. • A place where there is no obstacle near the air inlet and outlet. • A place which allows an easy installation of the piping to the outdoor unit. -

Page 23: Electrical Work

<When the installation plate is directly mounted on the wall> (1) Securely fit the installation plate onto the wall by screwing it in the upper and lower parts to hook up the indoor unit. (2) Install the installation plate horizontally in the wall. (3) To mount the installation plate on a concrete wall with anchor bolts, utilize the anchor bolt holes as shown in the above figure. -

Page 24: Wiring Connection

8-4-3. Wiring Connection WARNING To plug the cable in the plug receptacle, take the following precaution. THIS APPLIANCE MUST BE EARTHED. IMPORTANT THE WIRES IN THIS MAINS LEAD ARE COLORED IN ACCORDANCE WITH THE FOLLOWING CODE: : Brown -LIVE : Blue -NEUTRAL : Green and Yellow -EARTH... - Page 25 <How to connect the connecting cable> Wiring of the connecting cable can be carried out without removing of the front panel. (1) Remove the front panel. Fully open the front panel. Disengage the support arm located in the upper center while pushing its handle leftwards, and then remove the front panel toward you.

-

Page 26: Piping And Drain Hose Installation

8-4-4. Piping and Drain Hose Installation <In case of rightward piping> • After scribing slits of the front panel and the rear panel by a knife or a marking-off pin, cut them by a pair of nippers or the like. Slit (front panel) Slit (rear panel) Fig. -

Page 27: Indoor Unit Installation

8-4-5. Indoor Unit Installation (1) Pass the pipe through the hole in the wall, and hook the indoor unit on the installation plate at the upper hooks. (2) Swing the indoor unit to right and left to confirm that it is firmly hooked up on the installation plate. (3) While pressing the indoor unit onto the wall by the lower part, hook it up on the installation plate by the lower part. -

Page 28: Outdoor Unit

8-5. Outdoor Unit t Installation place • A place which provides the spaces around the outdoor unit as shown in the diagram in page 20. • A place which can bear the weight of the outdoor unit and does not allow an increase in noise level and vibration. -

Page 29: Refrigerant Piping Connection

8-5-1. Refrigerant Piping Connection <Flaring> (1) Cut the pipe with a pipe cutter. Obliquity 90˚ Fig. 8-5-2 (2) Insert a flare nut into the pipe, and flare the pipe. Outer diam. 6.35 mm 9.52 mm Pipe Fig. 8-5-3 <Tightening connection> Align the centers of the connecting pipes and tighten the flare nut as far as possible with your fingers. -

Page 30: Wiring Connection

CAUTION • KEEP IMPORTANT 4 POINTS FOR INSTAL- LATION (PIPING WORK) (1) Take away dust and moisture (Inside of the connecting pipes.) (2) Tight connection (between pipes and unit) (3) Evacuate the air in the connecting pipes using VACUUM PUMP. (4) Check gas leak (connected points) <Packed Valve Handling Precautions>... -

Page 31: Others

8-6. Others 8-6-1. Gas Leak Test Flare nut connections (indoor unit) Electric parts cover Flare nut connections (Outdoor unit) Valve stem cap connection Fig. 8-6-1 • Check the flare nut connections, valve stem cap connections and service cap connections for gas leak with a leak detector or soap water. -

Page 32: Troubleshooting Chart

TROUBLESHOOTING PROCEDURES : • Following details of “What to be pre-checked first”, make sure of the basic items. • When there is no trouble corresponding to above, check in detail the faulty parts following “How to judge faulty parts by symptoms” later. 9-1. -

Page 33: Misleading But Good Operations

9-1-3. Misleading but Good Operations (Program Controlled Operation) The microcomputer performs the operations listed in Table 9-1-1 to control the air conditioner. If a claim is made on the operation, check whether it corresponds to the contents in the Table 9-1-1. If it does, it is an indispensable operation for the control and mainte- nance of the air conditioner: it is not a failure of the unit. -

Page 34: Primary Judgement Of Trouble Sources

9-2. Primary Judgement of Trouble Sources 9-2-1. Role of Indoor Unit Controller The indoor unit controller receives the operation com- mands from the remote control and assumes the fol- lowing functions. • Measurement of the draft air temperature of the indoor heat exchanger by using the thermo sen- sor (TA). - Page 35 (2) Self-diagnosis with remote control With the indoor unit control, self-diagnosis of pro- tective circuit action can be done by turning the remote control operation into service mode, oper- ating the remote control, observing the remote control indicators and checking whether TIMER lamp flashes (5 Hz).

- Page 36 <Self-diagnosis by check codes> 1) The self-diagnosis by the check codes is con- ducted under the block displays of item B-H in Table 9-2-1. 2) Remote control key operation under the ser- vice mode is conducted by ON/OFF or TEMP. The remote control display by each key op- eration is varied as shown below.

- Page 37 Block level Check Check Block code code Indoor PC Thermo sensor board short/break. Heat exchanger sensor short/break. Indoor fan lock, abnormality of indoor fan. Abnormality of other indoor unit PC board. 1) Gas shortage. Refrigerant system 2) Other refrigerant 3) Heat exchanger 4) Overload relay Contents detected by the check codes “...

-

Page 38: Troubleshooting Flowcharts

9-3. Troubleshooting Flowcharts 9-3-1. Power can not be Turned on (No Operation at All) <Preliminary checks> (1) Is the supply voltage normal? (2) Is the connection to the AC output OK.? Shut off the power supply from AC outlet once and turn it on after 5 seconds. -

Page 39: Power Can Not Be Turned On After Replacing Indoor Pc Board

9-3-2. Power can not be Turned on after Replacing Indoor PC Board <Checking Procedure> Connect the AC Power supply Does the OPERATION lamp flash? Black White Indoor terminal block 9-3-3. Outdoor Unit does not Operate Shut off the power supply from AC outlet once and turn it on after 5 seconds. -

Page 40: Only Compressor Does Not Operate

9-3-4. Only Compressor does not Operate Shut off the power supply from AC outlet once and turn it on after 5 seconds. Does the OPERATION lamp flash? Does the power turn on by pushing the [START/STOP] button of the remote control? Is the voltage across the indoor terminal ( 1 - 2 ) 220/230/240 VAC? Is cable connection between indoor... -

Page 41: Only Outdoor Fan Does Not Operate

9-3-5. Only Outdoor Fan does not Operate Shut off the power supply from AC outlet once and turn it on after 5 seconds. Does the OPERATION lamp flash? Does the power turn on by pushing the [START/STOP] button of the remote control? Is the voltage across the indoor terminal ( 1 - 2 ) 220/230/240 VAC? Is cable connection between indoor... -

Page 42: Only The Indoor Fan Does Not Operate

9-3-6. Only the Indoor Fan does not Operate < Check procedure > Shut off the power supply once. Turn the power supply. Does the fan stop in no operating status? Start the operation with low fan setting in cool operation. Does the fan rotate? Change the setting of cooling to high fan. -

Page 43: How To Check The Remote Control (Including The Indoor Pc Board)

9-4. How to Check the Remote Control (Including the Indoor PC Board) Is there direct sunlight on the receptor of the air conditioner? Is there any thyristor fluorescent light near by? Keep the air conditioner away Avoid direct from thyristor sunlight. -

Page 44: How To Check The Pc Board

9-4-1. How to Check the PC Board (1) Operating precautions 1) When removing the front panel or the PC board, be sure to shut off the power supply. 2) When removing the PC board, hold the edge of the PC board and do not apply force to the parts. - Page 45 (3) Checking procedure Procedure Shut off the power supply and remove the PC board assembly from the electronic parts base. Remove the connecting cable from the terminal block. Remove the connector for the motor, and turn the power on. If the OPERATION lamp flashes (0.5 sec.

-

Page 46: Pc Board Layout

9-4-2. PC Board Layout Top View Bottom View – 46 –... -

Page 47: How To Reduce The Operation Time Of The Anti-Restart Timer

Table 9-4-2 Approximate value of the sensor (thermistor) resistance (TA, TC) Temperature Sensor Themo Sensor 9-4-3. How to Reduce the Operation Time of the Anti-Restart Timer • Attach the diode (1S1555 or equivalent) to the rivet inside the unit through holes on the rear of the wireless remote control unit. -

Page 48: Part Replacement

10-1. Indoor Unit (RAS-10SK-E, RAS-10SKX) Part name Front panel 1) After stopping the operation of the air conditioner, be sure to turn off the circuit breaker or disconnect the power plug from the AC wall socket. 2) Open the screw caps and remove the two screws fixing the front panel. - Page 49 Part name „ Horizontal grille 1) Perform the process Note: 2) Remove the screw fixing the louver motor, and remove the louver motor. The horizontal grille can not be 3) Remove the shaft of the horizontal grille from the removed without drain-pan.

-

Page 50: Microcomputer

10-2. Microcomputer (RAS-10SK-E, RAS-10SKX) Part name Common 1) Turn the power supply off to stop the operation of procedure air-conditioner, and disconnect the power cord from the AC supply. 2) Remove the front panel. • Remove the two fixing screws. ( 4 x 14 ) 3) Remove the electrical part base. -

Page 51: Outdoor Unit

10-3. Outdoor Unit (RAS-10SA-E, RAS-10SAX) Part name Common 1) Stop the operation of air-conditioner, and disconnect procedure the power cord from the AC supply. 2) Remove E-parts cover. (1- ST1T ø4 x 10 ) 3) Remove the cord clamp (2- ST2T ø4 x 12 ) and remove the connecting cable. -

Page 52: Cautions On Replacement Of Pc Board Assembly

11. CAUTIONS ON REPLACEMENT OF PC BOARD ASSEMBLY 1. Set the switch (SW03) provided on the PC board as follows. 2. Don?t wind the black lead wire around the current trans. (CT. T02) Black White Indoor terminal block Blue Brown RY01 Power terminal... -

Page 53: Exploded Views And Parts List

12. EXPLODED VIEWS AND PARTS LIST 12-1. Indoor Unit (1) Location Part 43T60002 Base, Terminal 3P , AC 300V, 20A 43T69004 Sensor, Heat Exchanger 10k , 25°C 43T69005 Sensor, Thermostat 10k , 25°C 43T60004 Fuse, Temperature 77°C Location Description – 53 – Part Description 43T69007 PC Board, WRS-LED... -

Page 54: Indoor Unit (2)

Indoor Unit (2) Location Part 43T00002 Front Panel Assembly 43T00003 Suction Grille 43T80001 Air Filter (L) 43T80002 Air Filter (R) 43T80003 Frame Filter 43T07004 Screw Cap (L) 43T07003 Screw Cap (R) 43T08007 LED Panel (10SK-E) 43T08005 LED Panel (10SKX) 43T19004 Accepted Signal Filter 43T09003 Horizontal Louver Assembly for Service 43T09004 Louver Assembly... -

Page 55: Outdoor Unit

12-2. Outdoor Unit 14 2 Location Part 43T19001 Guard Fan 43T20001 Fan, Propeller 43005037 Front Cabinet 43T43004 Condenser 43062193 Cover, E-Parts 43005038 Back Cabinet 43T47008 Capillary-Tube 1.5 DIA 43T46001 Packed Valve, 9.52 43T47002 Bonnet, 9.52 DIA 43T46002 Packed Valve, 6.35 43T47003 Bonnet, 6.35 DIA 43T21001 Fan-Motor UE6-21SJ5P 43T47001 Flange, Nut...